Material Handling

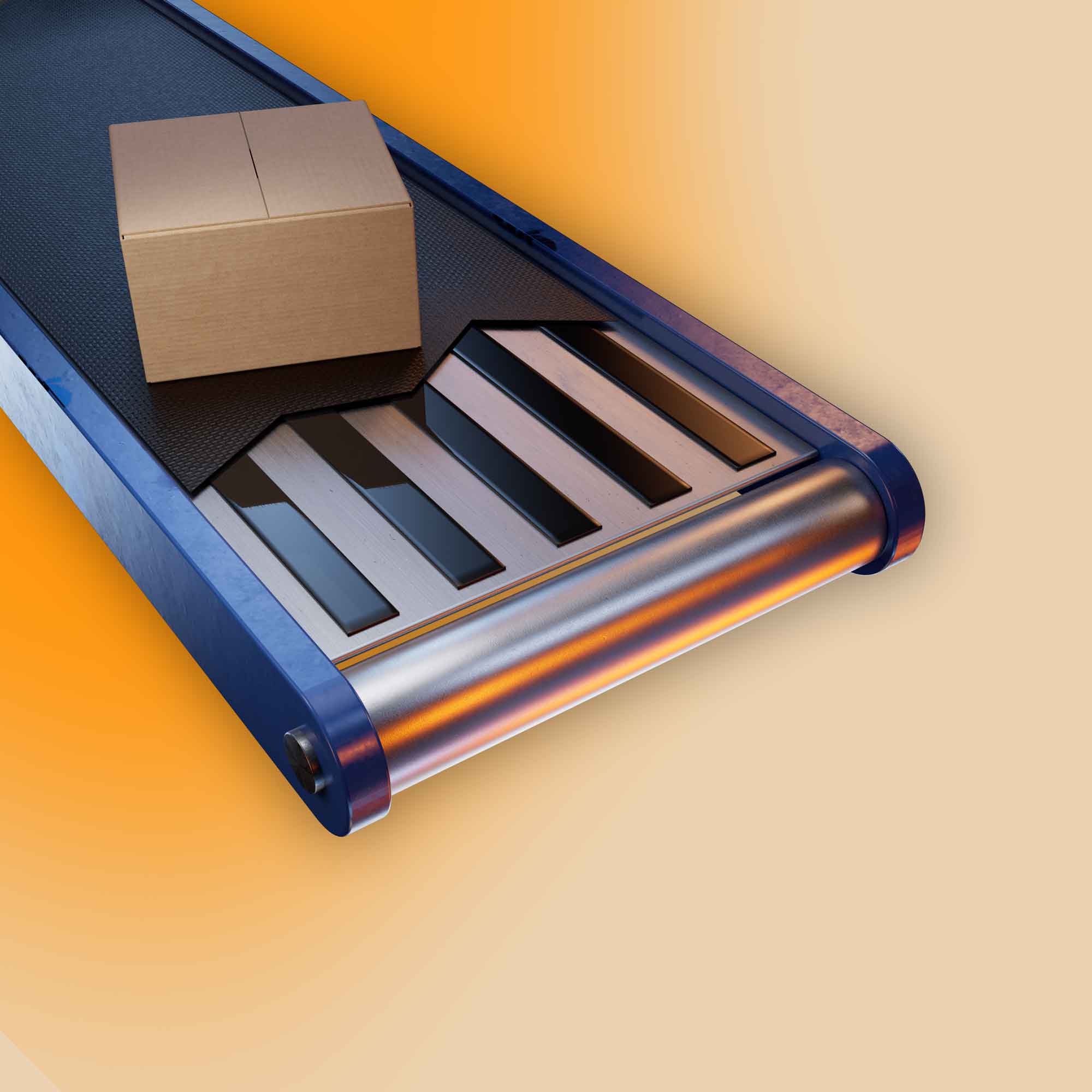

Get the slickest and most cost-effective solution for your custom chutes & material handling needs with Crown's turnkey solutions.

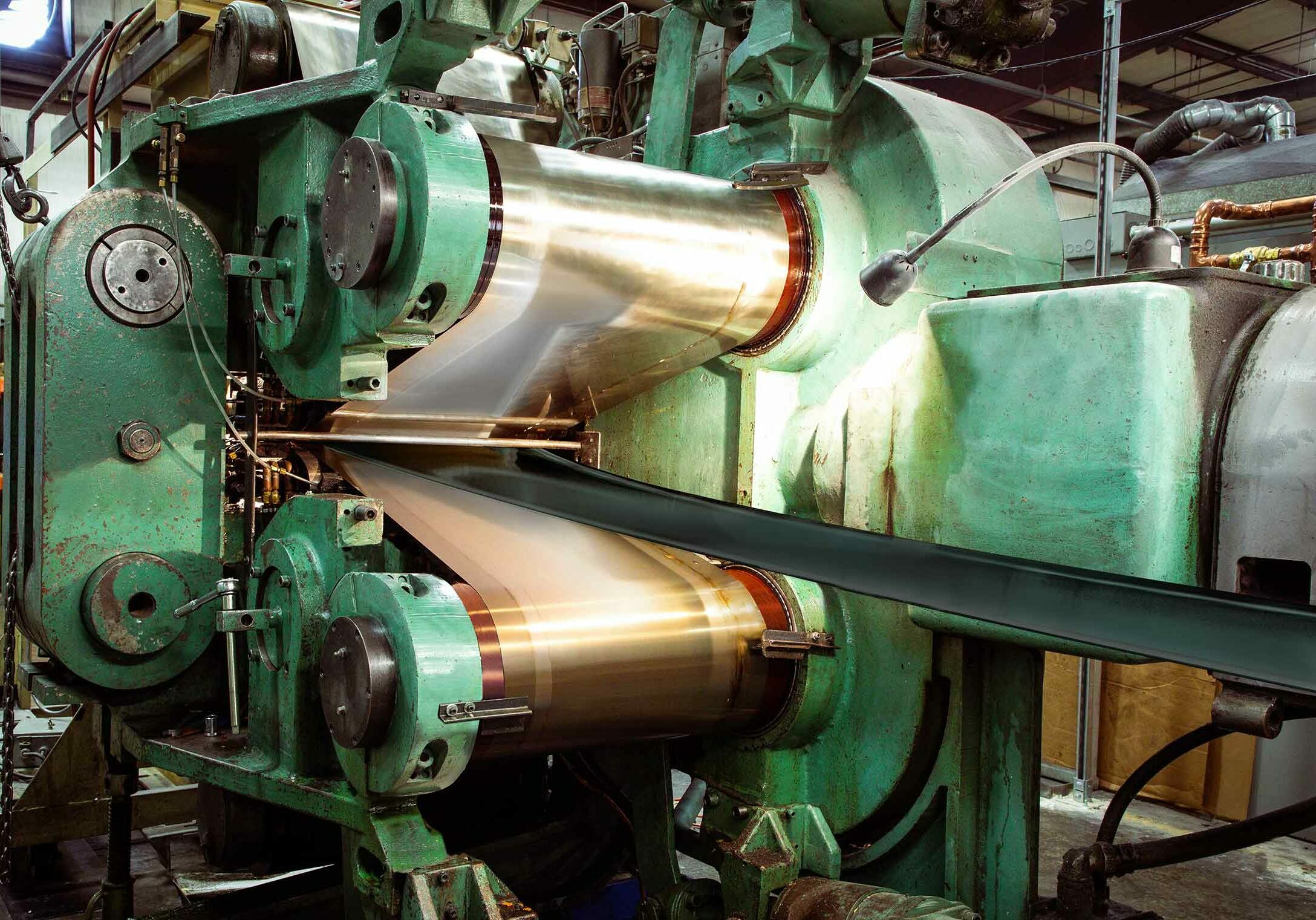

Crown’s unique Belt Press production method gives you the competitive edge you need by reducing scrap and eliminating unnecessary shipping & handling costs—while providing the highest quality UHMW. We don’t make chutes, we make the stuff that makes chutes work!

Get the slickest and most cost-effective solution for your custom chutes & material handling needs with Crown's turnkey solutions.

With Crown's unique Belt Press production method, you get the slickest, gold medal level UHMW for your boards.

Eliminate squeaks and whistles and extend the life of your vehicles with UHMW solutions from Crown.

Don't pay for scrap you can't use—we produce UHMW at any thickness between .030"-.30" at sizes that best meet the needs of your materials.

Crown is with you every step of the way, from manufacturing to design to installation. Save 30% by eliminating the shipping & handling costs others require to get the job done.

Our proprietary Belt Press technology and silicone-impregnated UHMW gives you the slickest finish, proven to last 14x longer than typical carbon steel.

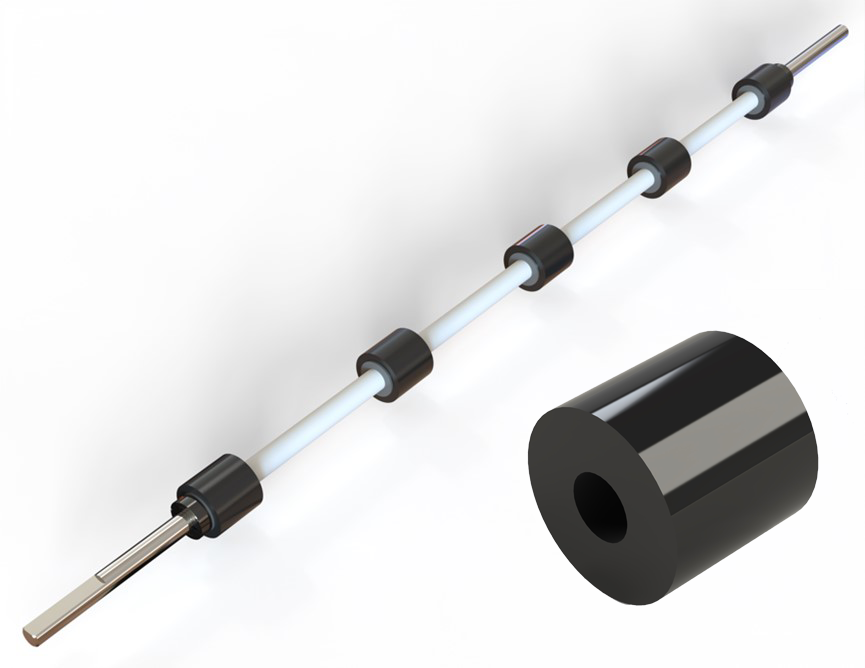

Our Silent Rollers are bearing-free, combining superior design and higher-quality materials to deliver exceptional performance with less noise for your conveyor systems.

Designed without ball bearings and using Crown’s UHMW, which offers greater wear resistance than stainless steel, Silent Rollers provide the best belt wear performance and protection. The result is less noise, better working conditions, less maintenance, and lower inventory costs!

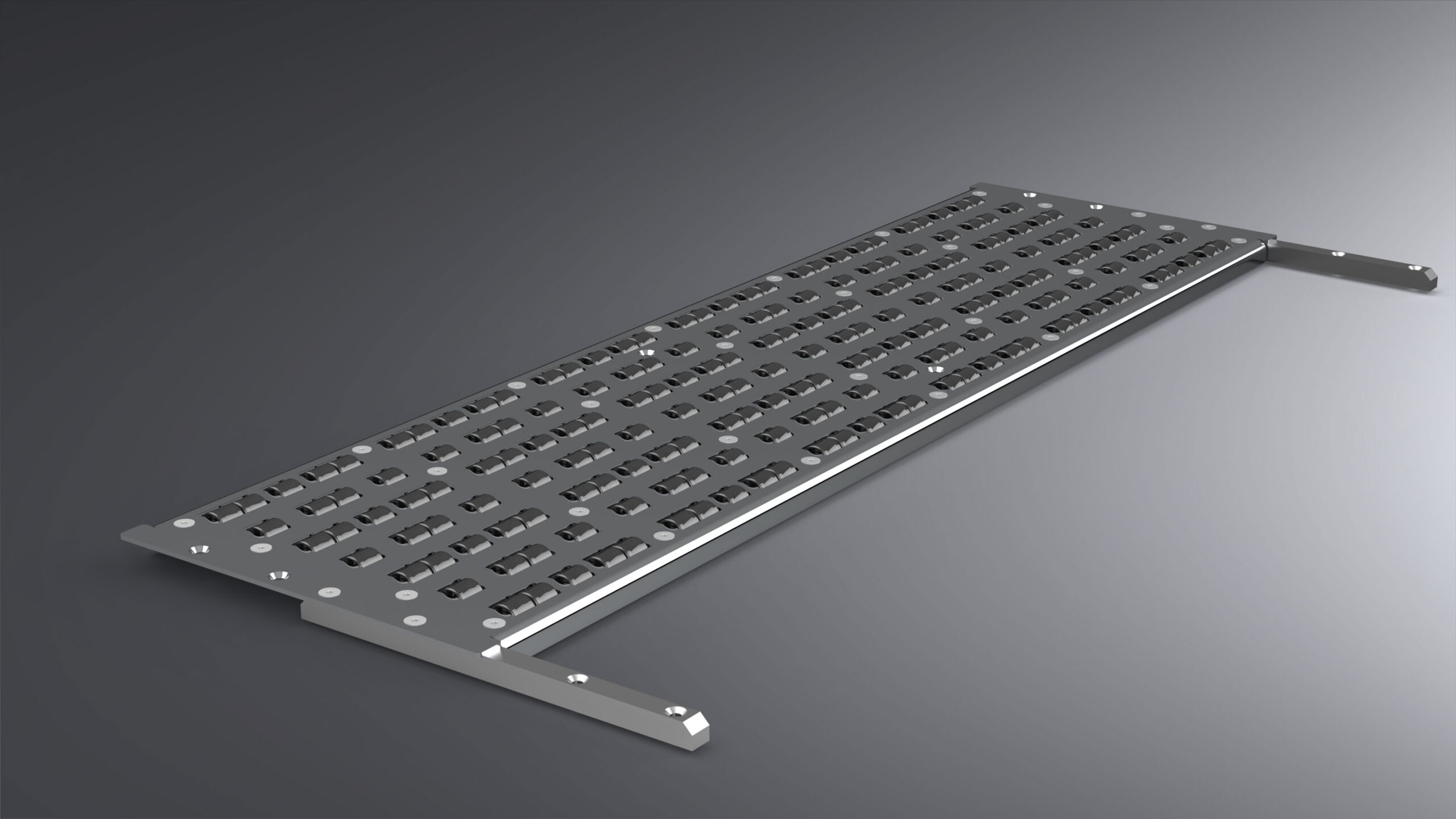

With an industry-leading design and superior materials, our Roller Plates to work for very low incline areas. They keep even light objects moving, but with the strength and durability to handle continuous high-impact and heavier loads.

Better design and better material make a better solution for high-volume and high-load areas for superior material handling performance!

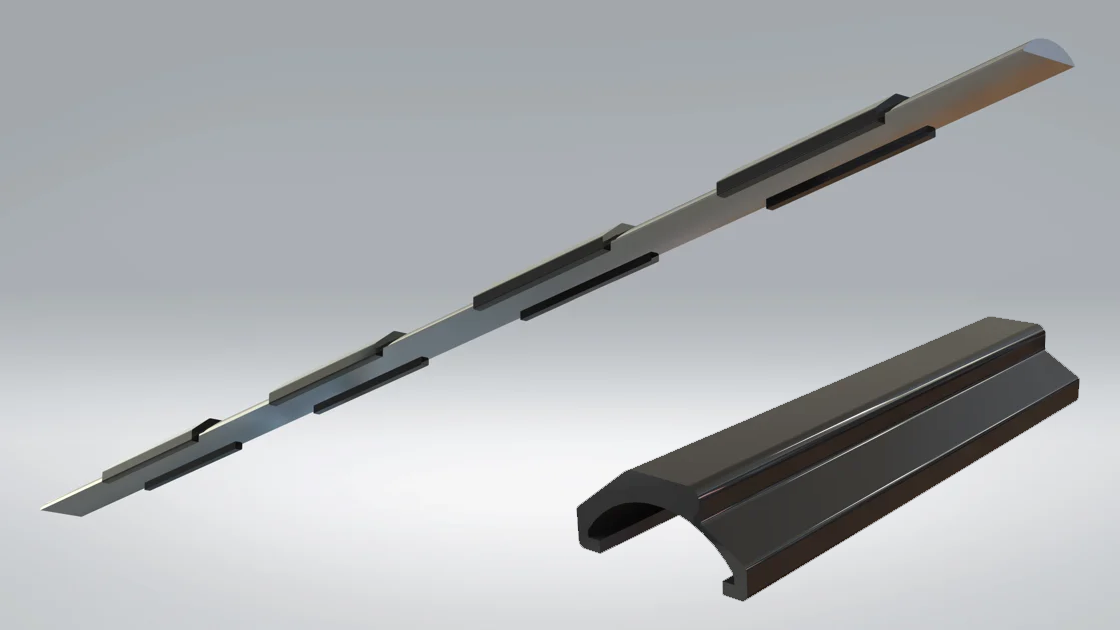

STS Durasurf™ Slider Strips extend the life of your systems and save maintenance costs, all while further reducing noise in your facility.

Crown Return Bar Covers are a simple solution to eliminate vibrations and reduce friction and amp draw. They snap on to the steel bars and install in minutes, creating a safer, quieter system that extends the life of belts, lacings, bars, and drives.

With three standard sizes (1.5”, 1.75”, and 2”) and at 6” in length, they fit all quarter-round bars. Orders come with 25 bar covers.

Crown’s unique Belt Press production method and end-to-end services mean you get higher quality materials—without the strain on your budget.

With only 7 belt presses in the world, Crown offers unrivaled technology that reduces scrap and provides a turnket solution—saving you time and money.

Request a QuoteTECHNOLOGY

Crown is the only company with the unique Belt Press technology, allowing us to provide UHMW with unrivaled quality and performance.

SERVICE

We're more than a UHMW manufacturer—from designing to installation, our turnkey solutions save you time and costs.

QUALITY

With silicone-impregnated options, Crown's Durasurf is the slickest UHMW with the smoothest finish you can find. We also have many ways to make our material adhesive-backed for easy installation.

PRODUCT

Crown's Belt Press technology allows for custom thickness between .030-.25" on panels sized to your needs, reducing wasted scrap.

Find a distributor close to you to start using Crown’s high quality, cost effective solutions for the material handling industry.

Find a DistributorSee how Crown’s DuraSurf™ stacks up against the alternatives: